By: Matt Neff, Willy West Cheese Coordinator

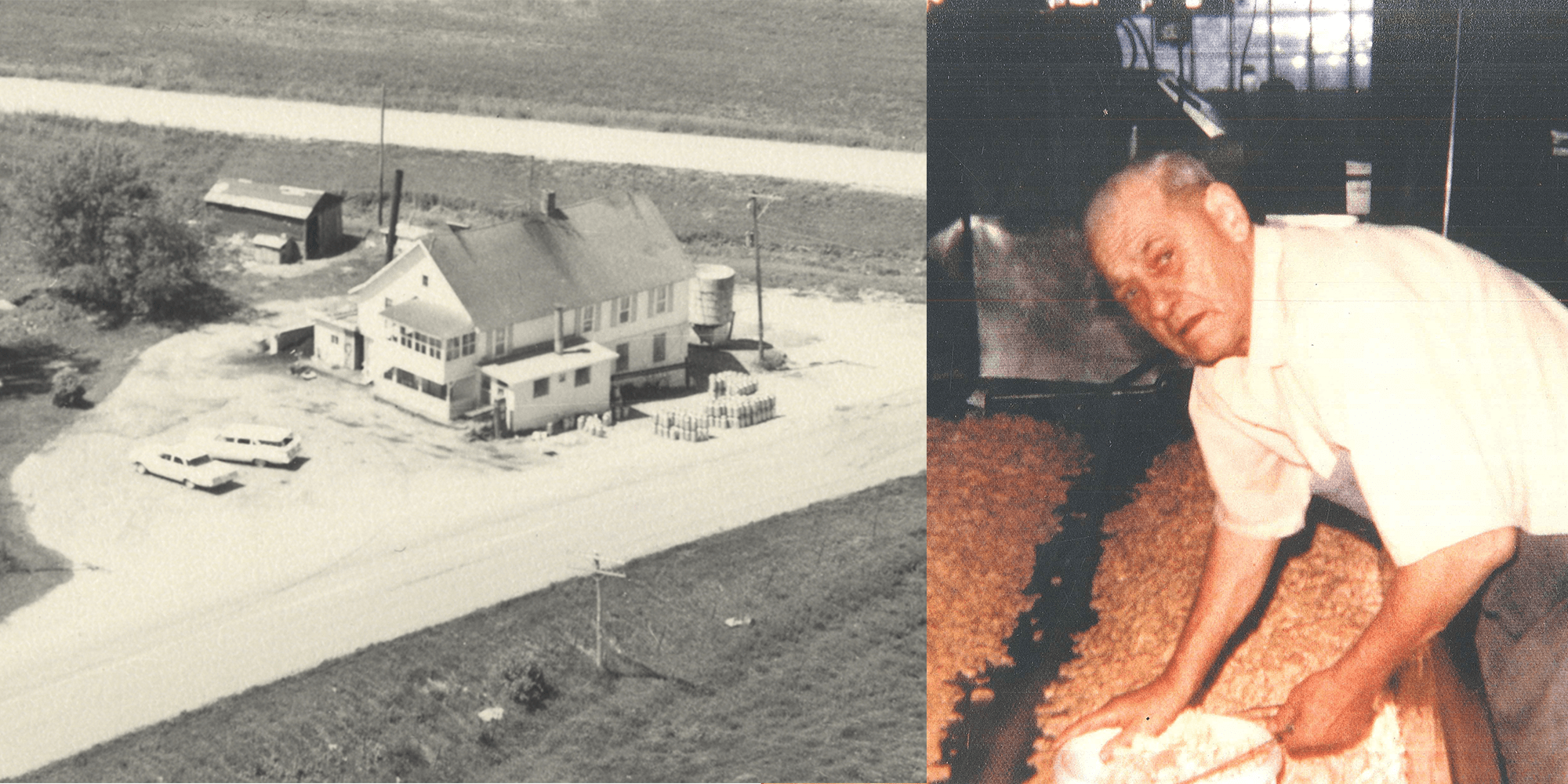

Among the scenic rolling hillsides of beautiful southwestern Wisconsin stand the offices, manufacturing facilities, and outbuildings of Meister Cheese Company, a fourth-generation family business that has been making cheese since 1916. The fine folks at Meister are Wisconsin cheesemaking heavyweights whose admirable qualities are already well-known to many locals.

But just what is it that makes Meister so unique and so wonderful, you ask? Apart from its obvious, primary mission of producing delicious cheese, Meister sets an excellent example with animal welfare, sustainability, and community environmental responsibility. Meister’s Cows First program is a company-designed animal welfare standard that ensures cows receive plentiful stall space, vegetarian feed, no artificial growth hormones, and free access to clean shelter, water, and pasture. The program was set up as the foundation of the company’s partnership with the restaurant chain Chipotle, for whom Meister supplies cheese nationally.

The crew at Meister are also the cool kids for the measures they have taken to mitigate their own environmental impact. In the process of extracting curds, cheesemaking generates a massive amount of whey. Meister established an adjacent whey-processing company (Muscoda Protein Products) in the early 1980s to process and dry whey protein concentrate and lactose, an innovative move at the time that alleviated the need to truck off the whey for disposal.

Even more impressively, in 2017 Meister invested in the construction of an onsite anaerobic wastewater biodigester. This water treatment system filters cheesemaking wastewater through a series of lagoons where anaerobic bacteria naturally breakdown organic matter, generating methane that powers an internal combustion engine that drives a generator. The wastewater is filtered and cleaned further before being released back out into the environment. This system reduces natural gas consumption and generates a hefty amount of electricity, and it earned Meister Energy Efficiency Excellence Award in 2019 from Focus on Energy, a statewide utilities program for energy efficiency and renewable energy.

To learn more about Meister and their operation, I talked with Meister spokesperson Michael Schaefer of Muscoda.

Matt: Meister came to our attention recently because our Prepared Foods and Cheese Category Manager, Nicholas OConnor, went on a tour meeting various Wisconsin cheesemakers and one of them was Meister. He hadn’t been aware of Meister’s sustainability efforts and their Cows First program, and he was very impressed with the Chipotle partnership. Can you tell us how Meister linked up with Chipotle initially?

Meister: The partnership started over 17 years ago when they were looking for a sustainable supplier who met the animal welfare requirements they have for their whole entire company and menu. They came to Southwestern Wisconsin and saw Meister cheese and said, “Ah, the rolling hills here in Southwestern Wisconsin and the small local family-owned farms where the cows are pretty much always outside as long as it’s not snowing—that’s where we want to get our cheese from, that’s where we want to source our milk from,” and that’s how the partnership started over 17 years ago. It’s been a great partnership.

We were pretty much already following their intended standards with how our dairy farming is done in this area, and some of the farms just had to make small adjustments to fit into their program. They have free-cell barns for each cow and 24/7 access to pasture, although it doesn’t mean they have to go out there—when it’s -20º outside the cows do NOT want to go outside, so they don’t have to. There’s no artificial hormones allowed to increase milk production, and the cows are fed a vegetarian-only diet. They have to have access to clean shelter, pasture, and fresh water as well. The farmers who follow this program get audited regularly, and they receive a premium on their milk. The average herd size for this program is about 125 cows, so they’re smaller farms, and that premium can go a long way. For all of our Meister brand products, the milk comes from those farms.

Matt: You’re located in Muscoda in the unglaciated Driftless region, which is such a wonderful ecological area—are your farms all located in the Driftless, or do they range outside of there? Do you feel like it gives you an advantage being located in the Driftless?

Meister: Most of them are within a 3-mile radius of our facility in Muscoda. Because of the nature of the Driftless region, that’s why so many farms meet the Cows First standards—there’s not many large industrial farms in this area, and there’s not many farms that crop because of the terrain and the rolling hills in this area—it’s better for dairy farms.

Matt: Muscoda is in the middle of morel country—have mushrooms always been incorporated into your cheesemaking? Was that a no-brainer?

Meister: There’s a pretty good story how that started—one of the third-generation owners, Vicki Thingvold (Scott Meister’s sister) would take different cheese recipes to the Dane County Farmer’s Market in Madison in the late 1990s and try them out there, and if people liked them, they’d roll with them and start selling them under our Meister brand. So that flavor started then, from taking it to the DCFM and receiving positive feedback. The two other flavors that we started the same way were our Muscoda Mayhem Colby Jack and our Bruschetta Jack. Those three have been staples for us and they’re still our top sellers.

Obviously Muscoda is the morel capitol of Wisconsin—we like to say of the world—so every year, near Mother’s Day, we have a large mushroom festival; we’re a small town of a thousand people and we double in size for a weekend and people come and buy morels like crazy.

Matt: Does Meister have any thoughts on the organic label? Is it something a lot of small or mid-sized dairy farms just consider to be too expensive? Do you think it still has a reputation of integrity? A lot of companies are producing their own certifications and their own standards to say, “we’re not paying for organic, but we’re pretty much as good as that.”

Meister: I think there’s regulations that make it more difficult on the farmers’ end and on our manufacturing end as well. There’s more regulations and that obviously becomes more difficult, so for some suppliers they just can’t quite get there to get that organic certification. For us, our Cows First program is about as close as we can get to organic, and we know where our milk comes from and we’re proud of it, and we’re definitely proud to put our Meister name on that milk and that cheese.

Matt: Do you have any favorite Meister cheeses or ways to eat them?

Meister: The morel and leek jack is our best seller under our Meister brand. Personally, I like to melt it onto a Wisconsin brat—a lot of people in our plant like to melt it on a baked potato, and sometimes they’ll use it to do a twist on a mushroom-Swiss burger, instead of using Swiss and mushrooms.

Matt: Do you have any Muscoda humor or stories you’d like to share with our readers?

Meister: We have a big plastic dairy cow named Daisy outside our cheese plant here. A few years ago she was actually stolen and she was found several weeks later, after news stories about the theft aired, about 30 miles down the road. She was undamaged and unhurt. They found her and brought her back.

If any members of the public have information about this crime, please call America’s Most Wanted at 1-800-CRIME-TV. For an up-close look at Meister’s sustainability operations, visit https://www.youtube.com/watch?v=ER_Tv2oE2_o .